Creating beautiful shiplap requires precision, skill, and the right table saw techniques. Woodworkers can transform ordinary lumber into stunning wall coverings by mastering specific cutting methods, understanding wood grain, and implementing strategic rabbet joints. This comprehensive guide will walk you through every critical step of making shiplap with a table saw, ensuring professional-quality results for your home renovation project.

What Tools Do You Need for Making Shiplap?

Essential Equipment Checklist

- Table saw with dado blade

- Measuring tape

- Pencil

- Safety glasses

- Hearing protection

- Push stick

- Dust mask

- Sandpaper (120-220 grit)

- Wood filler

How to Prepare Wood for Shiplap?

Before cutting, proper wood preparation is crucial. Follow these steps:

- Select Appropriate Lumber

- Choose straight, knot-free boards

- Recommended wood types: pine, cedar, poplar

-

Preferred thickness: 1/2 to 3/4 inch

-

Inspect Wood Quality

- Check for warping

- Ensure consistent moisture content

- Remove any visible defects

What Are the Precise Cutting Techniques?

Rabbet Joint Configuration

| Board Thickness | Rabbet Width | Rabbet Depth | Reveal |

|---|---|---|---|

| 1/2 inch | 1/2 inch | 1/4 inch | 1/4 inch |

| 3/4 inch | 3/4 inch | 3/8 inch | 1/4 inch |

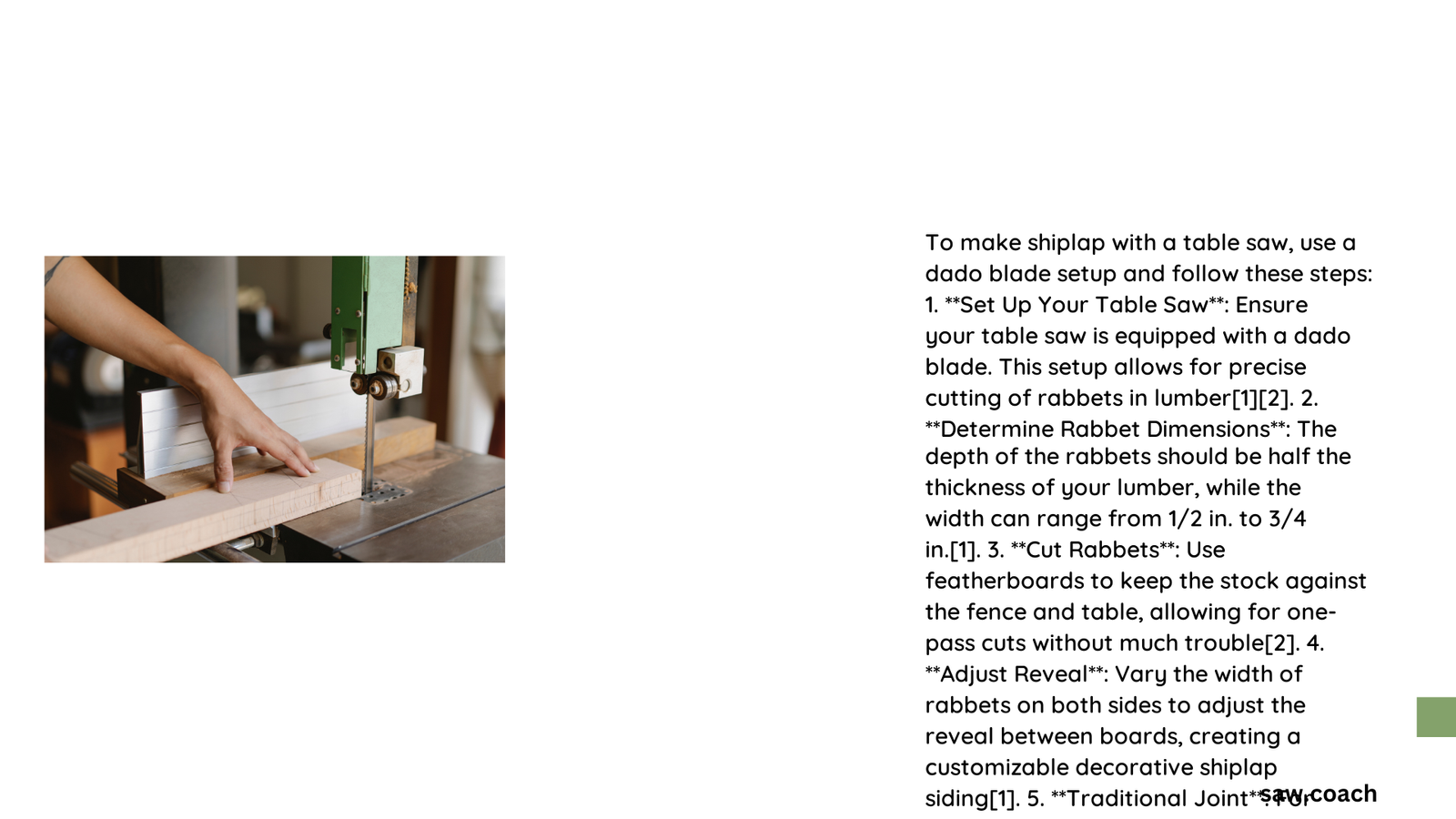

Cutting Process

- Set dado blade to half lumber thickness

- Adjust blade angle to 0 degrees

- Use steady, consistent feed rate

- Cut rabbets on both board edges

How to Ensure Safe Table Saw Operation?

Safety is paramount when making shiplap with table saw:

- Always wear protective equipment

- Keep workspace clean and organized

- Use push sticks for guiding wood

- Maintain blade sharpness

- Avoid loose clothing

- Work in well-lit area

What Finishing Techniques Enhance Shiplap?

Sanding and Refinement

- Start with coarse-grit sandpaper

- Progress to fine-grit for smooth finish

- Remove dust completely

- Apply wood filler if necessary

- Optional: Paint or stain boards

Pro Tips for Perfect Shiplap

- Measure twice, cut once

- Practice on scrap wood first

- Maintain consistent board width

- Allow wood to acclimate before cutting

- Use sharp blades for clean cuts

Common Mistakes to Avoid

- Inconsistent rabbet depths

- Incorrect blade height

- Rushing the cutting process

- Neglecting safety precautions

- Using inappropriate wood type

Troubleshooting Shiplap Challenges

Potential Issues and Solutions

| Problem | Solution |

|---|---|

| Splintering | Use sharp dado blade |

| Uneven joints | Adjust table saw precisely |

| Wood tear-out | Reduce feed rate |

| Inconsistent width | Use fence and guide |

Final Recommendations

Making shiplap with table saw requires patience, precision, and practice. By following these comprehensive guidelines, woodworkers can create professional-quality shiplap for various home improvement projects.

Pro Woodworker Insight

Invest time in understanding your tools and wood characteristics. Each project offers an opportunity to refine your skills and create stunning, custom woodwork.

Maintenance Tips

- Clean table saw after each use

- Regularly check blade alignment

- Store tools in dry environment

- Lubricate moving parts

Reference:

– Family Handyman Woodworking Guide

– Wood Magazine Techniques

– Popular Woodworking Resources