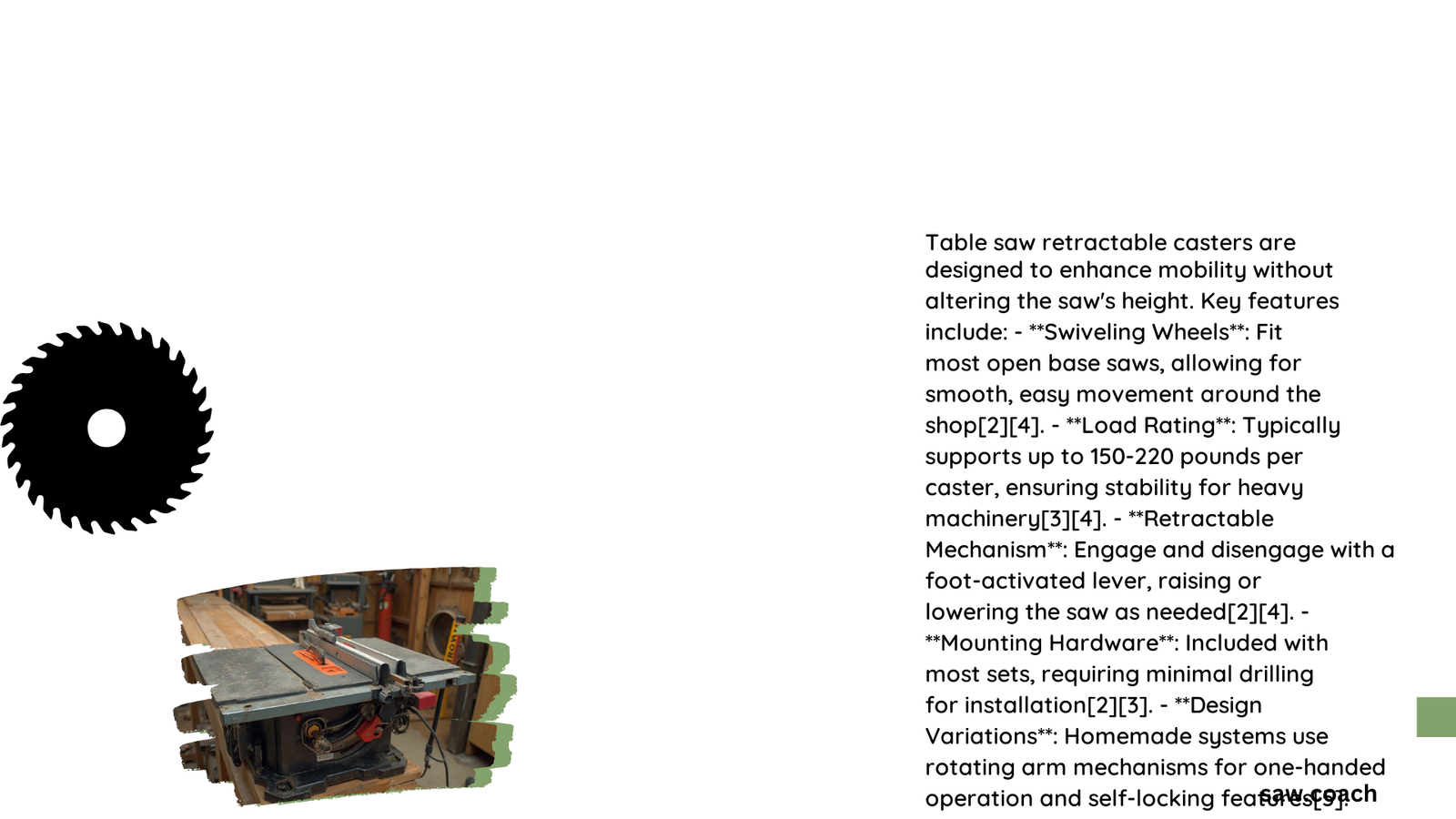

Table saw retractable casters are innovative mobility solutions designed to transform stationary woodworking equipment into easily movable workshop assets. These specialized casters enable woodworkers to effortlessly reposition heavy table saws while providing rock-solid stability during cutting operations. By integrating retractable wheel mechanisms, craftsmen can quickly switch between mobile transportation and stable work positioning, solving the perennial challenge of managing large, weighty power tools in limited workspace environments.

What Are Table Saw Retractable Casters?

Table saw retractable casters are specialized wheel systems engineered to provide woodworkers with flexible mobility options. Unlike traditional fixed casters, these innovative accessories feature a unique design that allows users to:

- Quickly move heavy table saws across workshop floors

- Instantly stabilize the saw for precise cutting operations

- Reduce physical strain during tool repositioning

- Maximize workspace efficiency

How Do Retractable Casters Work?

Retractable casters operate through a sophisticated mechanical system:

- Deployment Mechanism: Foot-operated lever

- Wheel Material: Typically polyurethane or polypropylene

- Frame Construction: Durable steel or reinforced metal

- Locking System: Ratchet-style engagement

What Weight Capacity Can You Expect?

| Caster Brand | Per Caster Capacity | Total Set Capacity |

|---|---|---|

| POWERTEC | 440 lbs | 1,760 lbs |

| WoodRiver | 150 lbs | 600 lbs |

| Peachtree | 150 lbs | 600 lbs |

What Should You Consider Before Purchase?

When selecting table saw retractable casters, evaluate these critical factors:

- Compatibility: Ensure matching mounting plate dimensions

- Weight Requirements: Match caster capacity with saw weight

- Wheel Diameter: Typically 2 inches for standard models

- Installation Complexity: Some models require drilling

Installation Best Practices

Successful caster installation demands meticulous preparation:

- Measure leg dimensions precisely

- Use appropriate mounting hardware

- Verify level surface after installation

- Test mobility and stability thoroughly

What Are Potential Challenges?

Woodworkers might encounter several challenges:

- Uneven workshop flooring

- Complex leg configurations

- Limited mounting space

- Potential stability issues with lightweight stands

Cost Considerations

Pricing for table saw retractable casters varies:

- Budget Range: $50 – $100 per set

- Premium Models: Up to $150

- Factors Affecting Price:

- Material quality

- Weight capacity

- Brand reputation

- Additional features

Maintenance Tips for Longevity

Extend your caster’s lifespan through:

- Regular wheel cleaning

- Periodic lubrication of moving parts

- Inspection for wear and tear

- Proper storage in dry environments

Expert Recommendations

Professional woodworkers suggest:

- Prioritize quality over cost

- Match casters to specific saw model

- Consider workshop floor conditions

- Invest in reputable brands

Conclusion

Table saw retractable casters represent a game-changing solution for workshop mobility. By understanding their mechanics, limitations, and benefits, woodworkers can make informed decisions that enhance workspace efficiency and tool management.